Who thought it was a good idea to ship volatile hazmat items in paint cans? Certainly no one who’s ever painted their living room.

First you need a screwdriver or a special “key” to pry the lid off the can, and it takes so much effort you end up sloshing some out onto the floor. Maybe you even stab yourself with the screwdriver! Then, when you’re done, you need a mallet to pound the lid back into place. Pound too hard, and you crimp the can; too softly, and the lid will pop off.

That’s a bad system for latex paint, and an even worse one for, say, sulfuric acid.

Some hazmat pros we know call it “Paint Can Hell.” And now we offer an alternative—one of two innovative new packaging designs for Dangerous Goods transport.

A 4GV assembled kit that banishes Paint Can Hell

If you’re using your own bottles or containers to ship high-value hazardous liquids, solids or other small articles by air, you’re likely to need a secondary container.

Until now, most shippers used a “paint can,” which seals like a standard can of white latex with all the shortcomings described above. People have actually been injured while opening them, which sort of undermines the point of shipping these substances safely.

Now, shippers in the chemical and pharma industries have a better alternative: our 4GV assembled kit.

These easy-to-use high-density polyethylene (HDPE) containers have a 119 mm screw-lid cap with a tear-off strip, so you don’t need any tools. It’s more rigid than a paint can at an equal or lower weight, and the tear-off band also serves as a tamper-evident seal.

These kits are ideal for smaller amounts of specialized, high-value chemicals and other hazardous substances. (For air shipments of liquids, you will need our reliable pressure bags.) With modifications, they can also be used for reverse logistics of biologic substances.

And you can say good-bye to Paint Can Hell.

Aircraft grade aluminum cases for shipping batteries 300wH or greater

With more and more consumers buying battery-powered lawnmowers, snowblowers, power tools and e-bikes, more and more shippers are transporting lithium batteries rated 300wH or higher.

If that’s you, your ideal shipping case has arrived: Custom Aluminum Case Battery Packaging.

These reusable cases are safe and compliant for ground transport of:

- Prototype lithium-ion batteries

- UN 38.3 tested lithium-ion batteries

- Lithium-ion batteries destined for recycle or disposal

- Damaged, defective or recalled lithium-ion batteries

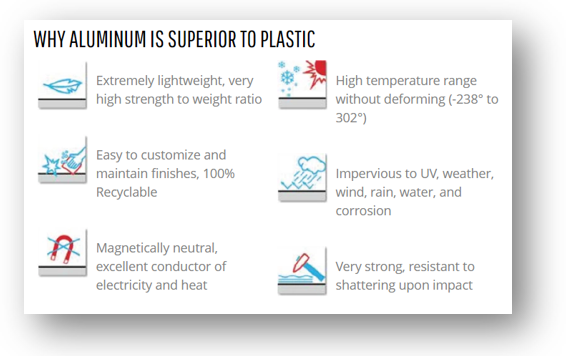

What makes them ideal? They’re constructed of aircraft grade aluminum, giving them excellent durability and weight savings with a smaller footprint. They’re handle the elements far better than containers made of plastic and other composites—they’re UV-, water-, weather- and corrosion-resistant and can withstand a temperature range of -238° to 302°F.

Most important for lithium battery transport: they’ve passed a fire test with 500 wH lithium batteries at a 100% state of charge, during which the fire was completely contained and filtered, the adjacent cells were undamaged and the exterior temperature never exceeded 100°C.

For lithium batteries and devices with batteries rated less than 300 wH, our advanced line of Obexion lithium battery packaging is still your simplest, safest solution. Now you have a better alternative for larger batteries, too.

Have questions about these packaging innovations, or any other hazmat packaging questions? Give us a call at 800.621.5808.

Make sure your shipments are safe and in complete compliance with a full line of solutions from Labelmaster—a full-service provider of goods and services for hazardous materials and Dangerous Goods professionals, shippers, transport operators and EH&S providers.