The 2021 Dangerous Goods Symposium got off to a rousing start this week, with four sessions covering everything from nuts-and-bolts regulatory updates to high-level ideas from leading executives on prioritizing DG compliance in a rapidly evolving supply chain.

Here’s a quick recap of those sessions, with links to watch the recordings on demand.

Further down, you’ll also find links to the rest of our two-week lineup. (All times are Central U.S.) You can also discover (and sign up for) all remaining Symposium sessions at the DG Exchange Events page.

Sign up now and catch all the essential sessions!

Supply chain CEOS and the stress reduction of DG compliance

According to the 2021 DG Global Confidence Outlook, only 38% of Dangerous Good pros strongly agree that their companies’ senior leaders are aware of DG supply chain challenges. Yet, with challenges such as eCommerce and the COVID-19 pandemic rocking global supply chains, hazmat compliance is more important than ever. What do corporate leaders need to know?

That’s the question at the heart of What the C-Suite Needs to Know About DG Supply Chain Management, a panel discussion including:

- Dave Crist, President of Brother Mobile Solutions

- R.J. Romano, Managing Director, BDO Consulting LLC

- Bruce Samuelson, Chief Executive at CHEMTREC®

- Bill Schroeder, President of ProShip, Inc.

- Rob Finn, Labelmaster VP of Marketing & Product Management

The most important theme to emerge may have been that superior hazmat compliance removes one source of stress from the equation, when so much else these days only adds stress.

“Now there are daily, sometimes hourly interrupts and disconnects,” says Crist. “And Murphy’s Law has been prevailing for a number of months.”

Romano adds, “A lot of our clients are dealing with ever-rising customer expectations, which puts a lot of stress on their supply chains. And it puts pressure on companies to rethink their investments. It’s not about cost-reduction, it’s about, “How do I make my supply chain more disruption-proof?’”

ProShip’s Schroeder cites a third source of stress. “Out of necessity, shippers are dropping packages into new networks they don’t fully understand. They’re onboarding regional carriers and the gig networks—they’ve got people picking stuff up in their cars! It’s amazing how creative and resilient they’re being, but they’re rushing into everything.”

Given all this added supply chain stress, the last thing a CEO needs is a Dangerous Goods incident that puts their company in the news—and that’s the value DG pros must lean on when lobbying for increased resources.

“The C-suite may be mentally grading you on an A-B-C-D-F scale, and they really only want to pay for a C,” says Samuelson. “But this is a pass-fail environment.”

Romano says, “Now is the easiest time to have conversations like this that aren’t associated with just cost reduction.”

Every CEO whose business involves the supply chain—and, really, whose doesn’t?—should watch this session to discover invaluable insights about the role of Dangerous Goods compliance processes in today’s climate.

What have we learned about virtual hazmat training?

Our panel of training experts and regulators answered that question in Let’s Talk Training! A Roundtable Discussion. They included:

- LaQuita Donald of Genuine Parts Company

- Scott Dunsmore of Lion Technology

- Geoff Leach of The Dangerous Goods Office, Ltd.

- Katelin Maits of PHMSA

- Jim Powell of Transportation Development Group LLC

- Rhonda Jessop, Labelmaster Director of Global Learning

All agreed there were benefits and drawbacks to virtual training. The benefits include cost savings and schedule flexibility, while the drawbacks included losing the human touch, keeping exams secure, and the difficulty of reading people’s faces when they’re wearing masks.

Donald stressed “the importance of internal SMEs and peer mentors. You need to foster a sense of community to help employees feel valued, and give them the resources they need to feel successful.”

Maits, meanwhile, pointed out that she performed inspections throughout the pandemic and saw a lot of training gaps—which she discussed further in her session the next day.

Essential insight from a PHMSA inspector

During What to Expect Before, During, and After a PHMSA Inspection, PHMSA Hazardous Materials Investigator Katelin Maits pointed out that the two most common violations found during an inspection—by far—are related to training and packaging closure.

Her best advice for making inspections less stressful is to “Have an inspection folder or binder with all the items an inspector will want to see, or a complete list of where they can be found.” These items include training records that your company may call by other names, and the location of special tools used for specific closure instructions.

“We know you don’t want us there,” she says, “and we’re sure to show up on your busiest day when you have employees out. Good organization will make your inspection a lot easier.”

Domestic regulatory updates—popular as always

Shane Kelley, Director, Standards and Rulemaking Division of PHMSA’s Office of Hazardous Materials Safety, and Vinny Desiderio, Hazardous Materials Program Specialist for the U.S. Postal Inspection Service, delivered one of the week’s most popular sessions with Domestic Regulatory Updates: PHMSA and USPIS.

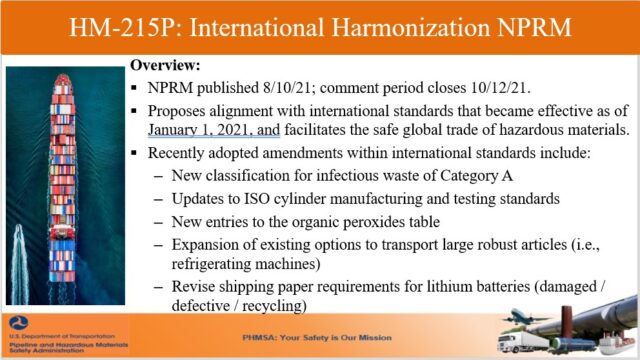

Kelley cites newly published HM-215P as “always one of our favorites—everyone wants harmonization, because no one wants to deal with conflicting regimes.”

Previewing a proposed rule, he adds that “It’s much easier to address comments during the notice process than trying to work backward after a rule is published—so please look through this ruling and send us a comment! This is the fun part for us.”

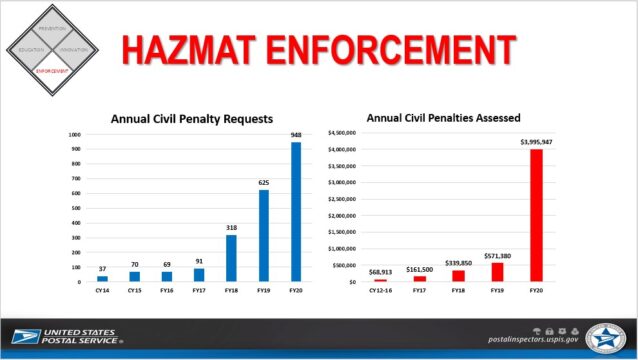

Desiderio, meanwhile, shares stories about his agency’s continuing efforts to stop illegal shipments of ammunition, calcium carbide, smoke grenades (for gender-reveal parties!), hydrochloric acid, chlorine tablets, strike-anywhere matches and other hazardous items.

He describes the exponential rise in penalties over the last few years, but says, “We like to think we’re having an effect but in reality, it’s a drop in the bucket. But we’d rather educate and prevent than enforce.”

Don’t miss these upcoming sessions!

Convince and Convert: What Makes Attention Getting Content for Your Audience, September 16, 10:00 AM CT, with marketing consultant Laura Denk.

IMDG Code Amendment 40-20 Update, September 16, 3:00 PM CT, with veteran Dangerous Goods consultant and trainer Richard Masters.

Live with the Lithium Battery Panel, September 17, 10:00 AM CT, with an all-star panel of experts from the regulatory world, aircraft manufacturing, airlines and training.

International Regulatory Updates: UN and ADR, September 20, 9:00 AM CT, with PHMSA’s Duane Pfund and Kristel Vermeersch, founder of KVS & Partners.

International Regulatory Updates: IATA & South America, September 20, 3:00 PM CT, with IATA’s Dave Brennan and CIQUIME Director Diego Gotelli.

Partners in Dangerous Goods – The FBI, September 21, 10:00 AM CT, with FBI chemist Dr. Charles Luman.

Are My Lithium Batteries Safe to Transport?, September 21, 3:00 PM CT, with a panel of Labelmaster experts.

Cybersecurity and Infrastructure & Chemical Facility Anti-Terrorism, September 22, 10:00 AM CT, with Mitch Paine and Sam Duchac, of the U.S. DHS Cybersecurity and Infrastructure Security Agency.

A Snapshot of Container Shipping 2021: The Suez Canal and Other Water Related Issues, September 22, 3:00 PM CT, with veteran Dangerous Goods consultant Richard Masters.

Optimized and Compliant: Let’s Review Your Shipping SOPs, September 23, 11:00 AM CT, with Pierbridge Senior Channel Manager Bob Liva and Labelmaster VP Mario Sagastume.

Understanding the Future of Freight Transportation, September 23, 3:00 PM CT, with FTR Chairman and CEO Eric Starks.

FAA Updates, September 24, 10:00 AM CT, with FAA Executive Director Ben Supko.

Dangerous Goods and the eCommerce Effect, September 24, 2:00 PM CT, with Dangerous Goods consultant Cathy Roberson.

Remember, this year’s event is all-virtual, hosted on the DG Exchange. (You’ll need a free DG Exchange membership to participate.) And that means three big benefits for you:

- It’s free.

- You can join as many (or as few) sessions as you want.

- You can watch them live or catch up with the recordings any time.

Don’t miss the Dangerous Goods event of the year—register now for the 2021 DG Symposium!

Make sure your shipments are safe and in complete compliance with a full line of solutions from Labelmaster—a full-service provider of goods and services for hazardous materials and Dangerous Goods professionals, shippers, transport operators and EH&S providers.