Because Mother Nature has no respect for your Dangerous Goods compliance record, we introduced hazmat labels, placards and marks for extreme conditions a few months ago.

Of course, our standard Dangerous Goods labels, marks and placards are DOT-compliant and more than durable enough to handle most normal shipping conditions without fading, peeling or losing adherence. But your shipments may sometimes face conditions that are anything but normal—and if your labels or placards fail, you’re looking at extra work or a returned shipment.

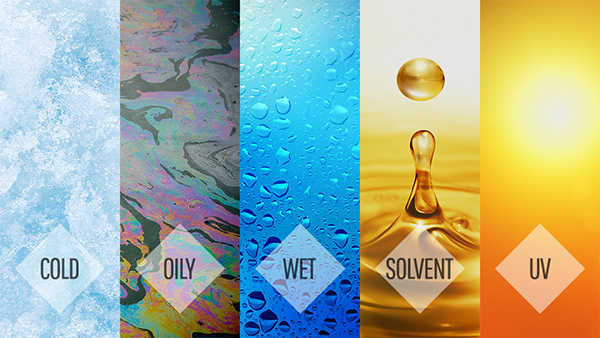

That’s why we created labels, marks and placards for these harsh conditions:

- Cold environments

- Oily surfaces

- Wet surfaces

- Solvent exposure

- Ultraviolet exposure

Labelmaster Product Manager–Labels and Placards Jill Resendiz has seen interest in these extreme labels, marks and placards take off in many of the areas we expected it would—and a few we didn’t expect. Here’s a look.

Summer’s the season for wet surface labels and placards

Labels and placards for wet surfaces found an immediate audience. “It’s hot and humid,” says Resendiz. “If your warehouse isn’t climate controlled, labels will keep falling off.”

A company with a Kentucky warehouse first tested Class 3 Flammable Liquid labels for wet surfaces in May 2019, with an order for 50 rolls. They were so pleased they’ve decided to flip all their labels over to the extreme versions. Resendiz says, “Over a year’s time, they’ve projected how much they can cut their total DOT label purchases by not having to replace all the labels that fall off.”

Another early customer was a Louisiana refinery that had problems with placards falling off tank cars on their short trip down to the docks. With Class 3 Flammable Liquid placards for wet surfaces, the problem was solved.

Oil-tolerant labels and placards are labor-saving

In some industries, cleaning the exterior surface of drums so they can accommodate labels and placards is a daily chore. And now it’s completely unnecessary.

Resendiz explains, “With most labels, if there’s any residue or surface contamination on the drum or container, if you don’t really prep the drum surface, the label won’t stick. Chances are your drum or container is being reused and is not pristine. You really have to prep the surface and follow the instructions from the label manufacturer.”

That’s not the case with our new oil-tolerant Class 8 Corrosive placards and Class 3 Flammable Liquid placards—they adhere to the drums’ surface without any pre-cleaning, as one customer learned.

“He said, ‘I don’t have time to do this,’ but with these labels there’s no preparation,” Resendiz says. “They’re saving a huge amount of time.”

A question of cost-benefit analysis

Does your organization need hazmat labels, placards and marks designed for extreme conditions?

That depends on your operation, obviously—but according to Resendiz, it’s really a question of cost-benefit analysis.

“Everybody is used to the way they’ve done it for 50 years—submit the same purchase order and don’t look beyond price. After all, this is a commodity market, and Labelmaster has the highest-quality labels, placards and markings. And any of them can be converted using the oil-tolerant material.

“You can keep on buying normal labels and keep on reapplying them. Or you can do a cost-benefit analysis that keeps track of the cost of repurchasing for all the labels you have to reapply. How do you want to look at your bottom line?”

She understands the new extreme labels won’t work in every operation—but believes many businesses will find them indispensable.

“Lots of places will never need these,” she says, “but why order two different stock items? It’s a lot easier to just pull one stock off the shelf than to choose one or the other. Make it simple.”

For a closer look at our new Dangerous Goods labels, placards and marks for harsh environments, visit our Extreme Conditions page.

Labelmaster is a full-service provider of goods and services for hazardous materials and Dangerous Goods professionals, shippers, transport operators and EH&S providers. See our full line of solutions at labelmaster.com.

I have a solución for placards in Extreme wind weather.i have haz mat with my Cdl and have problemas peeling the placards when i need to remove then.that is a problem when i put them to the tráiler in hot weather and then i have to remove then in freezing weather.not to say about trying to use then on freezing weather when i start my route,then if i use the aluminun frame they fly away, and i have to use tape. To keep them ..Y start working in this Project on my free time then dedicated mine 2 weeks vacación to finally have a good product .thank you for your time and i would like to offer a real all weather placard holder to your company..mi phone # 2154928122.mi name is Miguel and i have Been working with élite express for almost 20 years,thank you and i hope to hear from you.dios la bendiga.