Ask any Dangerous Goods pro about “paint can” secondary containers, and the response may require a parental warning for language.

You’ll hear about lids that won’t stay closed, or that can’t be pried open. You’ll hear about leaks in transit, smashed fingers from errant mallets, and ring locks that won’t come off without a power saw. You’ll hear about one-and-done cans that can’t be reused due to warps, dents and punctures.

But all these paint can shipper woes may soon be just memories. The paint can era is finally over.

Why? Because we’ve just introduced Capsuloc™—the next generation of hazmat shipping secondary container. It’s more reliable than the old paint can shipper, not to mention more convenient, easier, and leak-proof.

Capsuloc has been given a special permit (DOT-SP 21488) and accepted as exemption by UPS and FedEx, and has undergone rigorous UN testing, and (with a pressure tested primary container) can be compliantly shipped in its UN 4GV packaging kit by all modes of transportation.

Here’s a closer look at why you’ll soon be kicking the can.

Which secondary container does a better job?

This video explains Capsuloc’s advantage over paint can shippers with a side-by-side comparison.

If all that went a little fast for you—or if your job doesn’t require hands-on involvement with Dangerous Goods shipments—here’s a little more explanation.

A secondary container is one that isn’t intended to touch the hazardous material inside—its job is to provide extra containment if the primary container fails. For many hazardous liquids such as flammables, poisons and corrosive chemicals, a glass bottle like you see in the video is a widely used primary container. It’s typically used in a kit with an absorbent pouch, a secondary container, cushioning and a UN-specification box.

So which secondary container does a better job protecting that bottle?

As mentioned above, paint can containers often fail at secondary containment. If the primary container should happen to break, paint cans don’t always contain the leak.

Plus, paint can lids often require a mallet (or a machine) to close tightly, and a ring lock to make sure they stay sealed. And the cans damage easily, so they can’t be reused.

We created Capsuloc to eliminate those problems.

No headaches, lower costs

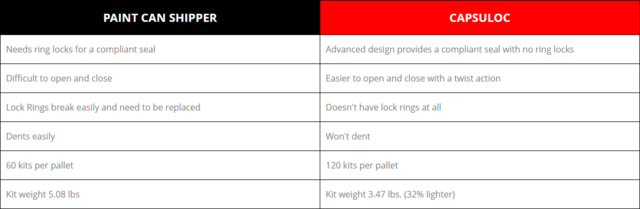

Here’s a handy look at all the paint can headaches Capsuloc can relieve:

Those last two items are especially important for operations looking to optimize resources and reduce costs—in other words, everyone. Capsuloc helps you:

- Save inventory space. Twice as many Capsuloc kits fit on a pallet, so you can keep more inventory in the same space.

- Save shipping costs. Capsuloc kits weigh 32% less than paint can kits, so they cost less per unit to ship.

In short, Capsuloc is easier to use, more reliable, more durable and more economical. Plus, it’s completely recyclable, made in the USA, and reusable over and over again (when you use a new UN fiberboard box kit and follow inspection criteria guidelines). That’s why hazmat operations are kicking the can and switching to Capsuloc.

Ready to kick the can?

Wondering whether Capsuloc is a fit for your operation? Call the experts at Labelmaster to discuss your materials, your workflows and all the details that go into making the best packaging decisions.

You may decide it’s time to stop cursing the paint can forever.

Make sure your shipments are safe and in complete compliance with a full line of solutions from Labelmaster—a full-service provider of goods and services for hazardous materials and Dangerous Goods professionals, shippers, transport operators and EH&S providers.