The final two sessions of Lithium Battery Week at the 2020 Dangerous Goods Symposium were explosive, in different ways. One session featured carriers, regulators, industry reps and top trainers squaring off on the hottest topic in hazmat transport, and other featured video of batteries actually blowing up.

Here’s a brief recap.

Let’s watch lithium batteries blow up!

Nick Warner is Cofounder and Principal of the Energy Storage Response Group, “the energy storage industry’s first and only complete provider for safety and emergency management solutions.”

In other words: They get paid to destroy batteries. Are they hiring?

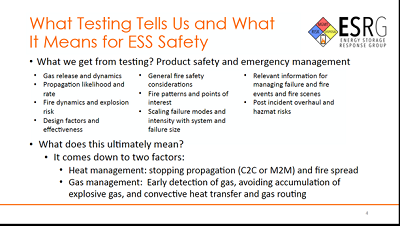

“It may sound corny,” said Warner, “but we consider ourselves a company ‘of firefighters, for firefighters.’ One of the main questions we answer is ‘What does a fire department need to know about why a battery is failing?’”

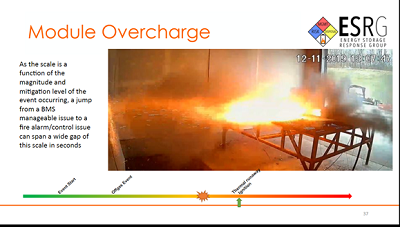

Warner’s teams run rigorous tests that involve penetrating fully charged batteries with nails and deliberately charging them to 200% state of charge. (You should really watch this session to see the videos!) One test literally blew open the doors of their test chamber; another generated 100 pounds of thrust, equivalent to a high velocity jet flame.

The goal, of course, isn’t to produce awesome videos but to help manufacturers make their products safer.

“We help manufacturers uncover the small design variations that can drastically affect how a battery fails—from very dangerous to incredibly benign,” said Warner. “If we can improve the time it takes for the situation to go off from five minutes to 65 minutes, that’s the difference between a major incident and time for a fire department to get there and get the situation under control.”

It’s also critical to educate emergency response teams about combating thermal runaway incidents, to avoid situations such as the 2019 explosion in Surprise, Arizona that injured eight firefighters. Warner said, “Very rarely does anyone responding have any idea what to do. Who needs to be involved and notified immediately? That’s why we need to investigate these failures.”

Watch the complete session here.

Fire away! The lithium battery panel is in session

Friday morning at Symposium felt like … Friday morning at Symposium. Even though we were all staring at our screens, the lithium battery panel was in session once again, and hazmat pros from all over the world were firing away with their best questions.

You should really watch the full session, but here are some topics that triggered spirited conversation (and a few choice responses):

On the SAE G27 packaging standards for lithium-ion battery packaging:

Michael Givens (FAA): “They’ve progressed relatively slowly. But one benefit is that all the research is acceleration for the UN classification group, which is looking at ways to more holistically covering lithium battery hazards.”

George Kerchner (PRBA): “I’m glad this is being recorded, because for the first time ever I agree with everything Michael Givens said. This will be a one-of-a-kind standard. The testing will be eye-opening, and there will be a lot of overlap with the UN subcommittee.”

On regulations allowing batteries shipped with equipment to be at 100% state of charge (rather than 30% for standalone batteries):

Michael Givens: When those regulations were put in place batteries had relatively low density and they were in large devices. They were based on the assumption that the large device would absorb a lot of heat, so they would be relatively low risk. We know enough now that we can’t assume anything. Batteries are getting larger and denser, and they’re powering devices that are getting smaller, so it turns the assumption on its head.

On verifying the “competence” in Competency Based Training through online assessments:

Geoff Leach (The Dangerous Goods Office, Ltd.): I’ve said we shouldn’t panic about Competency Based Training, as a lot of what we do in the classroom is establishing competence. In the virtual world it’s very difficult. We’ll likely have to see companies verifying the competence of their staff.

Dave Brennan: The regulations do say employers must establish competence.

Michael Givens: We don’t see a large change in the new requirements. If you can pass a test with 80% correct but still don’t know how to do the job? We don’t see that as an option under the current regulations.

Dave Brennan: Some people think it’s all new, but I disagree. It’s an evolution, not a revolution.

On stricter penalties (and potential alternatives) for Dangerous Goods violations:

Trevor Howard (Emirates): When you have a product manufactured in one country and shipped out of another, oversight is one of the biggest challenges. Operators fully support all initiatives, but how do we support them further down the supply chain?

Nick Warner: Only New York and California have rules for stationary battery storage; everywhere else it’s the wild west. In training, there’s a requirement for subject matter experts but there are no requirements about what constitutes subject matter expert. One place listed the guy who cuts the grass on the site.

Dave Brennan (IATA): A lot of the focus has been on transport, but have governments missed the boat? Should there have been cross-government efforts centered on consumer protection?

Michael Givens: At the FAA research Technical Center, we’ve had a fire safety branch since the 1960s< They’re not battery people but they’ve become experts. A lot of their research has brought these questions forward. You have submarines running on batteries, you have massive fires in ocean transport. Sometimes it takes an accident to realize it’s an area of concern.

Watch the complete session here.

Coming up at the DG Symposium

Thursday, Sept. 24: Regulatory Updates, Session 2. Duane Pfund (PHMSA), Dave Brennan (IATA) and Diego Gotelli (CIQUIME) share key regulatory updates from the UN, IATA/IACO and Latin America.

Thursday, Oct. 1: Chinese Regulatory Intricacies. Critical points to consider for any Dangerous Goods manufacturer or shipper with an eye on the Chinese market.

Make sure your shipments are safe and in complete compliance with a full line of solutions from Labelmaster—a full-service provider of goods and services for hazardous materials and Dangerous Goods professionals, shippers, transport operators and EH&S providers.