Why are we here?

Why are we here?

On one level, that’s an easy question. It’s Day 1 of the 2018 Dangerous Goods Symposium, and we’re here at the Loew’s Hotel in Rosemont, Illinois because this is the world’s premier event for Dangerous Goods shippers, trainers and regulators. We’re here to learn from each other and become more effective hazmat pros.

But … why? Why is Dangerous Goods compliance so important? As today’s sessions revealed, the answer to that question is evolving rapidly.

The Global Dangerous Goods Confidence Outlook

Representatives from Labelmaster, Hazardous Cargo Bulletin and IATA opened the Symposium by previewing the results of the third annual Global Dangerous Goods Confidence Outlook—the industry’s most comprehensive survey.

The largest-ever sampling of worldwide opinion on the hazmat industry included these remarkable figures:

- 95% believe DG enforcement is appropriate, or should be more severe.

- 67% believe DG training should be extended to other departments across their company.

- 54% wish their companies would understand that DG management could be a differentiator.

- 23% say their companies view compliance as a competitive advantage.

What’s the common thread?

“Companies can make a lot of money from shipping Dangerous Goods,” said IATA Assistant Director of Dangerous Goods Publications James Wyatt. “Go the extra mile, and you’ll be better than your competitors. When you talk about hazmat, ‘adequate’ is a wishy-washy word.”

HCB Editor-in-Chief Peter Mackay said, “More hazmat pros want enforcement tougher than want it looser. There’s a cost to compliance, and if you’re not complying you’re not paying it.”

“We DG pros need to talk to our leaders about the total value of compliance,” said Labelmaster Vice President of Marketing Rob Finn. “We talk about the cost of non-compliance, and it’s important, but there’s so much more. Companies with best-in-class compliance get more business and earn more revenue.”

In short, leading hazmat shippers no longer think of compliance as just a cost of doing business. They no longer even think of it as being solely about safety—although safety is still a prime motivator.

More and more, leading Dangerous Goods shippers view hazmat compliance as something that can deliver a huge return on investment, as long as they commit to continuous improvement.

Are competency assessments coming to hazmat training?

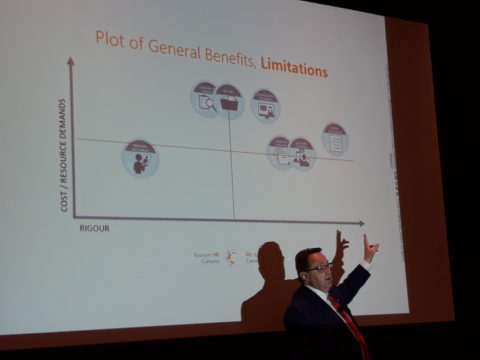

“Competency-based assessments,” said Philip Mondor, of Tourism HR Canada, “are a sexy subject.”

As competency-based hazmat training gains popularity, operations need a way to ensure trainees are actually gaining the competencies they’re being trained for. Competency assessments, Mondor said, are simply “measurement or evidence of a person’s knowledge and abilities, equating them to a specific standard, course or qualification.”

To accurately gauge competence, however, the assessment needs to be built to scientific standards of validity, reliability and fairness. In addition, Mondor said, “Criteria need to be explicit and in plain language. If they’re not well-defined, it’s all fiction.”

To accurately gauge competence, however, the assessment needs to be built to scientific standards of validity, reliability and fairness. In addition, Mondor said, “Criteria need to be explicit and in plain language. If they’re not well-defined, it’s all fiction.”

In an afternoon workshop with DG trainers, he outlined seven of the most popular forms of competency assessments:

- Written exams

- Structured interviews

- Demos, simulations

- Portfolios

- Reflective self-evaluation

- Collection of evidence

- Credentials/qualifications

“Dangerous Goods needs assessments at all three levels—diagnostic, formative and summative,” said Mondor. “Compliance is a competency in its own right.”

Training the new hazmat leader

Where are tomorrow’s Dangerous Goods leaders? LaQuita Donald, CHMM, CDGP, Environmental & Hazmat Compliance Manager at Motion Industries, Inc., said, “We have work to do in our industry.”

Her three-part prescription for creating tomorrow’s industry leadership: “Obtain the talent, train the talent and retain the talent.”

Since almost no one sets out to be a hazmat professional, “obtaining the talent” means defining your organization’s needs, then recognizing and nurturing people with the skills that the job requires—focus, communication and people skills. “Listening and hearing are different, and they’re both important. I can hear when people are about to go off the ledge, and I can reassure them it’s going to be okay.”

Since almost no one sets out to be a hazmat professional, “obtaining the talent” means defining your organization’s needs, then recognizing and nurturing people with the skills that the job requires—focus, communication and people skills. “Listening and hearing are different, and they’re both important. I can hear when people are about to go off the ledge, and I can reassure them it’s going to be okay.”

“Training the talent” can include internships, as long as they give trainees an idea of the real work environment. “If your shop is madness between 3:30 and 5:00, you want them to see that. They may not realize how physical it is. Sometimes, even the tape gun can be challenging.”

Considering how difficult it can be to find and train hazmat pros, “retaining the talent” may be the most critical part of the equation. “You need succession training, because life happens,” Donald said. “Do we write shadowing and mentoring into our processes? We should.”

Other highlights of a busy Day 1

During a morning session, PHMSA’s Shane Kelley urged hazmat pros to respond to the agency’s requests for comments: “We have a wide canvas for regulatory reform, so we need a lot of ideas.”

Samuel Duchac, of the U.S. Department of Homeland Security’s Office of Infrastructure Protection, recommended hazmat operations seek free inspections from Protective Security Advisors. “They’re Navy Seals with master’s degrees, SMEs in physical and cyber security. They’ll walk your property, and make recommendations for deploying resources. Some real GI Joe stuff here.”

The afternoon panel on “Creating and Developing a Corporate Compliance Program” reiterated the morning session’s emphasis on positioning DG compliance as a competitive advantage—and selling the C-Suite on the idea. The panel shared first steps, challenges and words of wisdom for making a strong compliance program a reality.

Tomorrow: The Global Regulatory Landscape panel, blockchain, and “The Future of Automation in the Hazmat World.”

Labelmaster is a full-service provider of goods and services for hazardous materials and Dangerous Goods professionals, shippers, transport operators and EH&S providers. See our full line of solutions at labelmaster.com.